|

Today, April 12 is a very special day at Tuba Inc. but especially for a precious collaborator "Liliane Dupont" our faithful Administrative Assistant whose 30 years of seniority we highlight! Present since the very beginnings of the company in 1993 and still very active with us, we are very proud to count day after day on her presence, her loyalty and her passion on a daily basis. Thank you for your important contribution to the organization and we wish each other good continuity together. From the whole team at TUBA INC

St-Pie-June 1, 2016, Despite the known hazards of the manufacturing sector, TUBA announces expansion of 60% therfore adding up 12,080 square feet to its production area. Taking advantage of increased demand from its customers, and always willing to support their growth, TUBA opens the machine and it is only the A phase of the operation with an initial investment of $ 1M. The Conference Board of Canada recently released its report, stating that "While many manufacturing industries are operating at full capacity, entrepreneurs are reluctant to invest" Tuba is certainly not part of these statistics.

Guy Côté, President: "Since 2008, we are all aware that industrial subcontracting has suffered ups and downs, for all sorts of reasons, but our customers are loyal and as such, the actual work of a subcontractor is to support and especially anticipate the needs of its clients, what we do and they appreciate. To have a supplier who is ready for any eventuality, should a rapid growth of production happen is certainly an added value in our industry right now, and that is what we are ". This expansion will increase its total area to 38,880 square feet and will be able to accommodate the new equipment recently purchased among others, cranes with a lifting capacity of 5 tons. The remodeled floor will also ensure greater fluidity to the production areas. TUBA is a specialized manufacturer since 1993 in the metal fabricating and more specifically in the precision tube bending and assembly of welded parts, both for steel and aluminum. Tuba operates exclusively in the context of subcontracting for short and medium production runs. "We are confident that this good news which will delight our existing customers and potential customers for who advanced technologies and respect for values and timelines are a priority," concluded Guy Côté, President. Originally published here.

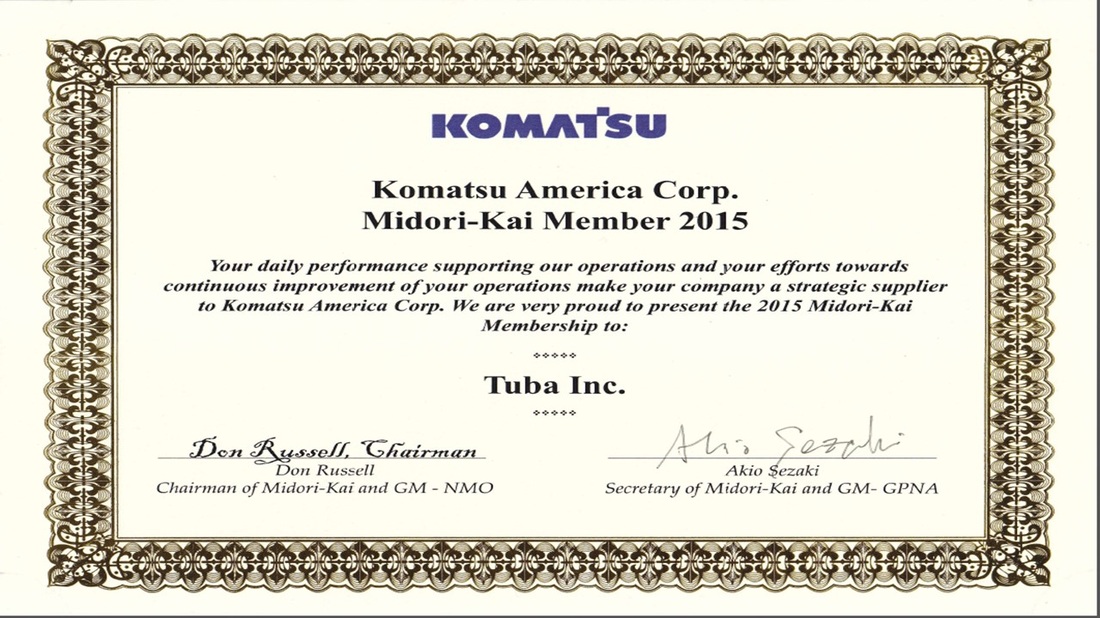

Last July 14th TUBA and its CEO Guy Côté, while in Chicago, received the official MIDORI-KAI supplier elite certification for 2015. This great recognition was given by Komatsu, to confirm the great performance offered byTUBA as a supplier. TUBA is therefore member of an elite club of 39 suppliers in North America, and remains since 2007 even if Komatsu closed their plant in Candiac Qc in 2009. TUBA now delivers the manufactured parts in Newberry South Carolina at Komatsu plant, This is great recognition of performance, also with delivery time, reaching Komatsu’s requirements like a 100% mark for their suppliers. Bianca Battistini, communications du Salon virtuel en transport terrestre  La Presse: A User-friendly Tool (Un outil convivial) by Martin Primeau In 1993, Guy Côté took over the bankrupt company to focus its activities on the specific niche market of precision bending and thus specialize in the bending of three-dimensional metal structures. In its facilities located in Saint-Pie, Tuba manufactures parts, which range from simple footrests to bumpers to components for bus chassis frames, on behalf of its transportation industry clients. Not just anyone can work at this manufacturing SMB. To work on the machines requires training and this training is not provided by educational institutions, but by the company. Tuba President and owner Guy Côté explains: “When it comes to punch presses and bending machines, you learn how to use them on the job.” And so, Tuba created an internal training program for employees to make sure that the knowledge of the senior staff is passed on to its new machinists and welders. “When people leave, knowledge leaves with them. We were concerned about losing that knowledge,” he added. — Guy Côté, President and owner of Tuba Created more than 10 years ago with a human resources specialist, the program has proven to be beneficial. But the President of Tuba seized an opportunity to update the program recently. Contacted by Parcours Formation, a competency development centre targeting companies and run by the Saint-Hyacinthe School Board, Guy Côté took part in a pilot project which involved transferring his paper-based training program onto a tablet. The project was managed by Parcours Formation in association with the Centre facilitant la recherche et l’innovation dans les organisations (CEFRIO). More User-friendly Our expertise on security and precision bending is now available electronically on tablets. New employees are always assisted by a mentor, in addition to benefitting from a user-friendly pedagogical tool that uses multimedia. According to Guy Côté, “People learn more quickly, because it’s highly visual, using video, pictures, and graphics with relevant comments. It’s not at all complicated.” This new tool also helps current employees learn to operate tools that they never dared to before. Guy Côté sees this as a bonus since Tuba is called upon to manufacture parts in small- and medium-size runs, and therefore needs its employees to be versatile. « On a vraiment poussé notre programme de formation d’un cran », dit Guy côté, enthousiaste au possible. “We seriously improved our training program,” said Guy Côté with great enthusiasm. “This tool is here to stay.” http://plus.lapresse.ca/screens/4e61-ed3c-533d832b-bf01-6b5eac1c606d%7CJbSN2PqjcxtC.html |

|

Tuba English

|

222 Jacques-Cartier Street

P.O. Box 339 Saint-Pie, Quebec J0H 1W0 Canada Tel.: 450 772-6767 Toll free: 1 800 567-1907 Fax: 450 772-6722 |

Our site has been optimized for the most recent versions of Internet Explorer, Chrome, Firefox and Safari.

A version of our site is available for IOS and Android devices.

A version of our site is available for IOS and Android devices.

RSS Feed

RSS Feed